No-Code Predictive Maintenance & Quality Control

Machine Learning for Manufacturing

Build predictive models from your manufacturing data without coding expertise. Create tools for equipment failure prediction, quality control, and production optimization using a straightforward, no-code platform.

Explore Platformuse client

Manufacturing ML Features

Platform Capabilities

Key functionalities that enable manufacturing teams to build and deploy machine learning models without specialized expertise.

Multiple

Data Types

Process time-series, categorical, and numerical data.

Various

Model Types

Classification for defect detection, regression for forecasting.

Automated

Retraining

Update models with new production data automatically.

Configurable

Alerts

Set thresholds for maintenance and quality alerts.

Production Optimization Tools

Manufacturing ML Applications

Build specific machine learning models for predictive maintenance, quality control, and production planning.

Automated Machine Learning

Upload manufacturing data and build predictive models without coding expertise.

Manufacturing Pipelines

Create reusable ML workflows that can be retrained as new production data becomes available.

Predictive Maintenance Models

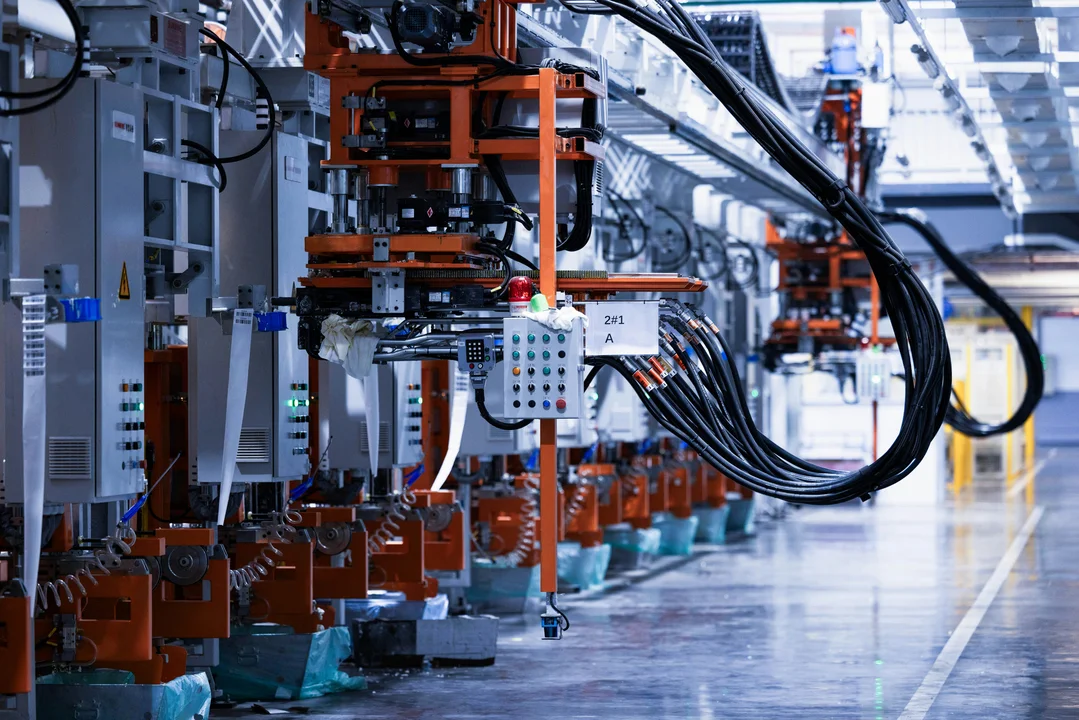

Train models that predict equipment failures and maintenance needs based on sensor data.

Production Analysis Interface

Input equipment variables and receive predictions for potential failures or quality issues.

Predictive Maintenance

Machine Learning for Equipment Reliability

Build models that predict when equipment will need maintenance based on sensor data. ML Clever analyzes patterns from historical maintenance records and equipment sensor readings to identify early warning signs of potential failures, helping reduce unplanned downtime.

Production Planning

Optimize Manufacturing Resources

Forecast production output and resource needs using historical data. Build models that predict how changes to production parameters will affect output quantity and quality, helping manufacturing teams make data-driven decisions about resource allocation and scheduling.

From Data to Predictions

Manufacturing ML Tools

Build, deploy, and use machine learning models specifically designed for manufacturing applications.

Predictive Maintenance Models

Train models that analyze equipment sensor data to predict failures before they happen, reducing unplanned downtime.

Make a Prediction

Prediction Result

Equipment Analysis Interface

Input current equipment parameters and receive predictions about potential failures or maintenance needs.

Production Monitoring Dashboards

Create visual displays of production metrics, equipment status, and prediction alerts for operations teams.

Automated Model Building

Upload manufacturing data and let the system build the best prediction model for your specific needs.

Quality Control

Predict Production Quality Issues

Create models that forecast which production batches may have quality issues based on process variables. The platform lets you identify which factors most influence product quality, enabling proactive adjustments to manufacturing parameters before defects occur.

How It Works

A straightforward process for creating manufacturing prediction models without coding or data science expertise.

Data Upload

Flexible

Import CSV files with sensor and production data from your manufacturing systems.

Model Building

Automated

Select what to predict (equipment failures, quality issues) and the system handles the rest.

Deployment

Simple

Use models through the web interface or connect via API to your existing systems.

Platform Performance

Implementation Metrics

How quickly manufacturing teams can build and deploy machine learning models.

Model Building

No-Code

Create prediction models without programming.

Data Processing

Automated

Process sensor and production data automatically.

Implementation

Days

Deploy manufacturing models in days, not months.

Manufacturing Use Cases

Specific applications of machine learning in manufacturing settings using the MLClever platform.

Equipment Reliability

- Failure PredictionProactive

Identify potential equipment failures days or weeks before they occur.

- Maintenance SchedulingOptimized

Schedule maintenance when it's needed, not based on fixed intervals.

Production Efficiency

- Yield OptimizationData-Driven

Identify optimal production parameters to maximize output quality and quantity.

- Resource PlanningPredictive

Forecast material and staffing needs based on production schedules and demand.